INTRODUCTION

Operation management is said to be a department which, for conducting a business operations optimises all the resources that are available to them. This assist the company in manufacturing goods with best quality. According to the case scenario a company wants to launch a 58' inch television, for this they are developing a proper plan that is further discussed in this report. Hotpoint is the organisation that is being taken in this assignment (Blomquist and et. al., 2010). The report will focus on implementation of operations management and its principles within an organisation. Therefore, a continuous improvement in plan is being done so that product can be effective in nature. All stages of PLC is discussed in this assignment for completing this report. Lastly, review is being done in order to know the effectiveness of PLC in chosen project.

Increase Your Odds of Success With Our

- Scholastic academic documents

- Pocket friendly prices

- Assured reliability, authenticity & excellence

TASK 1

P1 Implementation of project management in an organisation along with its principles

In an company there are various department that play their role so as to execute the work in a better manner. Operation management helps the organisation in practising different kinds of strategies by using raw materials for making a final goods and can be sell to its end customers. Thus, it can be said that this department helps the company in converting all the raw materials into final goods.

Therefore, for performing all the task in a better manner, operation management assist the company in designing and controlling the entire process of production so that it can be executed in an effective manner. Hence, the department of operational management is solely responsible for the planning and organising the activities (Brauers and Zavadskas, 2010). In context with Hotpoint they are following some of the principles in order to make the product the more efficient.

Principles of operational management:

Reality: While performing the task the operational management focus mainly on the problem than optimising new technologies. In this, company is using all the resources for making a product and avoid the factors that cannot add any value to the commodity. Other then this, they are focusing on the latest tools that are according to the current market situation.

Fundamentals: There are certain rules which are to be followed by the companies under Pare-to role that can be implemented in the operations. This includes strict laws which assist the organisation in managing the records to around 80% in success income before incorporating tools and 20% after implementing recent technologies at are available in the market area.

Accountability: Under this step, rules and regulations are formed and company give complete freedom to managers for making strategies which can provide them maximum benefits. Thus, they take consider the views of their team mates for doing the same. Along with this, they guide and motivate their employee for performing their task in a better manner.

Managed passion: Working with enthusiasm always provides benefits to the organisation as maximum number of production is done. This helps the company in giving better outcomes to its customers (Burke, 2013). Therefore, by providing good facilities, organisation is improving its brand image.

Success: Company manufacture goods for achieving success and profit in the business operations. For this, they are making appropriate strategies through which company can get to know about the changes they want to implement in their product or business.

Change: With the change in course of time new technologies and pattern are evolving, this is creating problem for companies to manufacture goods. Thus, company is taking feedbacks form their customer so as to understand the behaviour of consumers.

Henceforth, all the elements are looked by the department of operation management while manufacturing a new product and this is helping them in increasing their market shares and value in the market area.

Six Sigma: This concept is used by most of the companies so as to improve the quality of product. Through this, operational management tries to eliminate flaws and defects that can occur in the commodity (Corder, McLellan and Green, 2010). Therefore, it helps an organisation in reducing the cost and time that will be consumed while manufacturing the product. Other than this, it assist firm in resolving the issues and problems.

SIX SIGMA has a major tool i.e. DMAIC which is explained below:

Define: This is the first step, that helps management in recognising customer's demands and needs so that a new product can be made.

Measure: After analysing the process this come into being, all the resources are looked in order to meet future requirements for achieving goals.

Analyse: Evaluation of basic problems so that it can be eliminated while manufacturing a commodity. This helps the management in analysing the changes that are to be done.

Improve: Through latest tools and technologies, it helps the firm in rectifying the modifications that are required to be done for making the product more reliable.

Control: This is an important factor so that company can use minimum resources for getting an effective product.

Lean Principle: In context with Hotpoint, this is helping the organisation in generating ideas within the firm. This can be further understood by the points that are explained below:

Define value: Through this, company can analyse the nature of customers regarding the price they are agree to pay for nay commodity. This approach goes form top-down model. Firm's main focus is on costing so that their set targets can be achieved by minimising the waste in order to get maximum benefits at low cost as well (Cruz and Marques, 2011).

Map Value Stream: This assist the company in analysing each and every step of product like cycle, starting from converting raw material to final product so that it can be delivered to its end customers. It includes all the elements like designing, manufacturing, production, administration and many more. Therefore, it draws a blueprint of the activity which company has to follow, systematic process, excluding unwanted steps etc., thus, it can be used for excluding unwanted steps that are not adding any value to the product.

Create Flow: This comes after the process of map value system and it make the entire process go smoothly without any repetition, interpretation or delay. Thus, under this all the activities are done in a systematic manner.

Establish Pull: Through this, organisation tries to identify the process form which they can execute their activities in an effective manner (Fernández-Sánchez and Rodríguez-López, 2010). This enables company in managing all the resources in appropriate manner.

Pursue Perfection: Perfection cannot be achieved unless it is not improved on a continuous basis. Therefore, it is important for companies to accept changes so as to make the product more effective.

TASK 2

P2 Continuity in improvement plan based on review and analysis

Continuous Improvement And Its Meaning

This is determined as a process through which company does modifications in their products it is helpful organisation in understanding shortcomings in the commodity. Continuous improvement every time provides a better product than the preceding one. Therefore, it assist firm in improving the sales and profitability of the company. Apart from this, establish a better understanding of between customers and enterprise.

CONTINUOUS IMPROVEMENT PLAN

|

Source |

Anticipated Outcome |

Recent performance level |

Improvement in strategies |

|

Promotional events |

Because of low promotion of the product, maximum number of people are not aware of the commodities company has launched (Garel, 2013 ). As a result it is not in reach of every person. |

According to the current market scenario, their marketing practice is low because of which customers are in a dilemma whether to buy their products or not. Inappropriate communication of message can be seen. |

They are optimising all the resources and latest tools and technologies. Along with this the are using different kinds of promotional activities for delivering the right message to its customers. |

|

After sales services |

There is a perception that after selling the product company will not revert back their queries. |

In context with customers, they think that the warranty period of the product must be increased to a certain period.

|

Company is planning to develop a new department that will look after the queries asked by the customers. It will enable them in reverting back the issues in a better manner. Moreover it will improve the brand image of the product in front of its customers. |

Continuous improvement plan and its effect

With the help of above discussed factors it can be evaluated that, if company does a proper planning than it can turn out to be the effective tool for increasing their sales and productivity. In context with Hotpoint, they have implemented new and innovative ideas for making their product more reliable and effective. All these are incorporated by the organisation for promoting their activities in an appropriate manner. Further more, it will help firm in evaluating the areas where changes are needed so as to make the product perfect.

Therefore, managers of Hotpoint, is conducting a research in order to know the issues that are facing by customers regarding any commodity (Gunasekaran and Ngai, 2012). Thus, for this, company is planning better strategies which they can implement in their future proceedings.

Henceforth, organisation making plan of action so that they can deliver best quality products that are best in class. Along with this, they are ensuring that effective services and facilities are also provided by them. If customers face any issues regarding the goods than they are free to call register their queries and these will be reverted in short period of time.

Effective strategies for implementation of continuous improvement plan

The entire process of continuous improvement plan is managed by the manager of the firm and for this, they go through the feedbacks and reviews that are given by customers. Thus, it gives an overview about the modifications that required to be done in the product so that it can add value to the commodity. Therefore, it will help them in making changes according to the needs and wants of the customers. Other than this, some of the points are included that company can apply for making further improvements in their commodities and these are follows:

Good employee employer relationship: For attaining better growth in business it is essential that a healthy relationship is maintained between customers and organisation. Through this, company will have a better understanding of the region where they have established their business.

Proper communication channel: In order to reach to maximum number of people it is required that company use effective tools of communication through which they can convey their message to its end customers and employees as well. This is also help them in establishing an appropriate environment at workplace.

Priority to employees need: Managers of Hotpoint must make sure that they give attention opt their employees so that they can work effectively for increasing the sales and profitability of the company.

Proper guidance and direction: Here the role of managers are important as they should encourage and give guidance to employees in order to gain maximum benefits from their activities.This will help them in achieving their set targets and goals in specific period of time.

Organizational Theories, Models and Concepts

According to this current market scenario, various models are available which company can adopt for improving their sales and profitability. This includes theories like scientific, classical, bureaucratic and many more (Kerzner and Kerzner, 2017). It will help them in operating their business in an effective manner. Thus, all these theories are helping them in managing and organising all activities in a systematic way so that all the task are accomplished step by step. Apart form this, mentoring of the performance on a regular basis will help the manager in evaluating the data properly as a result it will help management in decision making.

TASK 3

P3 Application of Product Life Cycle

The mentioned company, Hotpoint wants to launch a new product i.e. a television of bigger size upto 58 inches. For this, it is essential that they make proper planning in order to know the required material for manufacturing and launching as well. In the market there are different kinds of source through which they can enhance the productivity and sales for a long period of time. For analysing the market durability it includes some of the factors like cost of productivity, features and many more. Research and development department must look for the genuine element that can act as a barrier in the entire business operations. Company are thinking of discovering a innovative product with features like smart button, UV reflective screen etc., this will provides them with competitive advancement in business environment. Along with this company must go through the strategies that are applied by them as it will help Hotpoint in making their product more effective in nature.

Product life cycle is an essential marketing process that is optimised by firms in order to develop their product in a proper manner (Lindström and et. al. ,2012). It provides with the detailed information about the process which will be helpful in developing a commodity in a better manner. In order to know if the product is giving effective results than they must observe their durability in the market area whether it is increasing or decreasing.

Product life cycle stages

Introduction stage: It is considered as a starting phase of manufacturing a product, it is important because after this step, every other step will be followed. Thus, it is determined as the initial stage of production process. Here, manager plays an important role of formulating business strategies so that they can forecast demand so that they can get effective results and outcomes. Initially the value of product is low but as the step progresses it gradually increases. For better outcomes, they are making policies so that customers can get best quality products. This will take around 4-5 weeks that is sufficient for accomplishing the entire process.

Growth stage: This is determine as second stage ans in this company uses raw material for manufacturing their final products. This step improve the sales of the company so that they can sustain a better position at market area. Therefore, it assist the organisation in generating more and more revenues. So, new television will take around 6-7 weeks so as to become stable in the market.

Maturity stage: This step is higher as compared other stages, in this company tries to introduce their brands which can fulfil the demands of customers by satisfying their needs and wants. For making it flexible in nature it is essential that they apply some of the innovative ideas, which can give them maximum benefits. For completing the entire process it will take around 8-10 weeks which is sufficient.

Decline stage: Under this stage, demand of the product comes to an end that is why it is consider as a negative stage. Therefore, it is essential for the companies to take proper steps through which they can avoid the product to come into this category.

Henceforth, this kind of concept is very suitable for analysing the efforts of managers. Along with this, they must also consider some of the roles dome by leaders in order to measure and analyse the position of product in market areas (Mir and Pinnington, 2014). Apart form this, the department of operational management must focus on evaluating the performance of employees so that management can implement activities for improving their existing skills and knowledge. Thus, it can be evaluated that the main aim of product development is to provide better facilities and services in order to attract more and more customers towards their company. This will help the organisation in hitting their set targets and objectives in specific period of time.

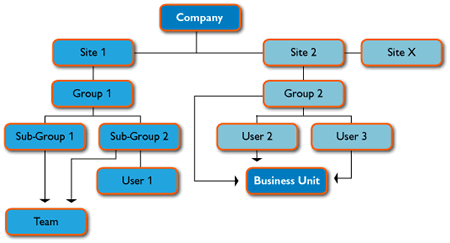

Below work down structure is mentioned for a new commodity:

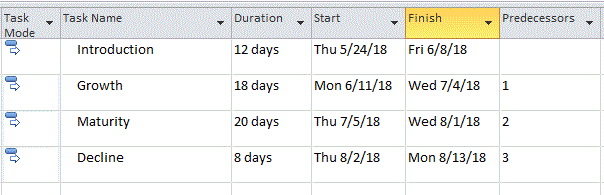

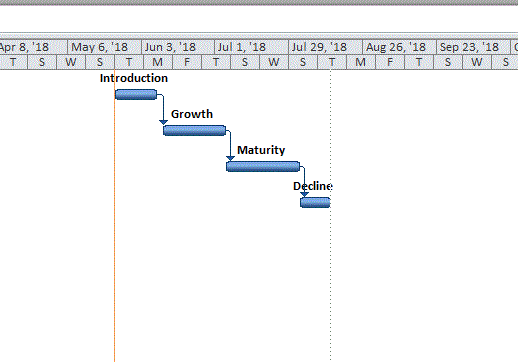

Gantt Chart: It is considered as a concept which is used for formulating a proper plan in order to work in a systematic manner. This helps the organisation in eliminating those factors that doesn't add any value to the product. Therefore, it gives information about the proper optimisation of resources for getting better results.

Illustration 1: (Gantt Chart Activity)

TASK 4

P4 Effectiveness of PLC in application of project

Hopoint wants to launch a new product i.e. a television of 58' inches as the company has a reputed image in the market area so trying a new thing will not be easier for them. It is prime role of manager to encourage their employees in order to make some changes so as to enhance their position at market area. As the mechanism of developing a television is quite difficult so they are giving proper training to their workers so that they can manufacture best quality products which can be delivered to its end customers.

Although Product life cycle stage provides maximum benefits but applying it is not a easy task because in order to develop a product it has to go through various stages. Thus, to make it into reality company is developing strategies and plan of action so as to fulfil their desired goals and objectives (Ogunlana, 2010). Therefore, superiors can conduct a meeting and discuss about different policies which can be applied for getting effective results. By taking feedbacks from customer in order to know their preferences company can develop the product more effectively. Thus, to sustain in the m,market for a longer period of time firm must make sure that commodities that they are made by them are giving satisfaction to its clients.

Making of strategies is not the only task to do, implementing it in a better manner is the point. As the company is making television for the first time so, it is essential that they manufacture a product which is excellent in quality so that customer doesn't feel disappointed after purchasing their commodity. Along with this, company must ensure that even after selling their products they give better services and facilities to its clients. For this, they have developed as separate department who will handle the entire process of queries and taking feedbacks from its customers. It is enabling them, in giving better reverts of their clients and because of which they are improving their brand image in front of their customers.

Apart from this, in order to increase their sales they are offering discount to their first 100 customers which is seems like a very good policy in context with Hotpoint. For conducting the process of Product life cycle it is important to have better plans so that it can be implemented for taking better decisions (Pade-Khene, Mallinson and Sewry, 2011).

Henceforth, there are various factors that are present in the market area and company can optimise for getting effective results. In case of Hotpoint, they are considering all the points for manufacturing the products in a better manner.

CONCLUSION

From the above mentioned it can be concluded that, operational management is one of the important department that is providing company with better services and facilities in context with increasing their sales and profitability. Under this, leaders and manager plays a prominent role by guiding their employees in order to give their best performance. Therefore, it is enabling company in gaining a better position at market area.

You may also like to read:

REFERENCES

- Blomquist, T. and et. al., 2010. Projectaspractice: In search of project management research that matters. Project Management Journal. 41(1). pp.5-16.

- Brauers, W. K. M. and Zavadskas, E. K., 2010. Project management by MULTIMOORA as an instrument for transition economies. Technological and Economic Development of Economy. 16(1). pp.5-24.

- Burke, R., 2013. Project management: planning and control techniques. New Jersey, USA.

- Corder, G .D., McLellan, B .C. and Green, S., 2010. Incorporating sustainable development principles into minerals processing design and operation: SUSOP®. Minerals Engineering. 23(3). pp.175-181.

- Cruz, C. O. and Marques, R. C., 2011. Contribution to the study of PPP arrangements in airport development, management and operation. Transport Policy. 18(2). pp.392-400.

- Fernández-Sánchez, G. and Rodríguez-López, F., 2010. A methodology to identify sustainability indicators in construction project management—Application to infrastructure projects in Spain. Ecological Indicators. 10(6). pp.1193-1201.

- Garel, G., 2013. A history of project management models: From pre-models to the standard models. International Journal of Project Management. 31(5). pp.663-669.

- Gunasekaran, A. and Ngai, E. W., 2012. The future of operations management: an outlook and analysis. International Journal of Production Economics. 135(2). pp.687-701.

- Kerzner, H. and Kerzner, H. R., 2017. Project management: a systems approach to planning, scheduling, and controlling. John Wiley & Sons.

- Lindström, J. and et. al. ,2012. A development process for Functional Products: hardware, software, service support system and management of operation. International Journal of Product Development. 16(3-4). pp.284-303.

- Mir, F. A. and Pinnington, A. H., 2014. Exploring the value of project management: linking project management performance and project success. International journal of project management. 32(2). pp.202-217.

- Ogunlana, S .O., 2010. Beyond the ‘iron triangle’: Stakeholder perception of key performance indicators (KPIs) for large-scale public sector development projects. International journal of project management. 28(3). pp.228-236.

- Pade-Khene, C., Mallinson, B. and Sewry, D., 2011. Sustainable rural ICT project management practice for developing countries: investigating the Dwesa and RUMEP projects. Information Technology for Development. 17(3). pp.187-212.

- Pemsel, S. and Wiewiora, A., 2013. Project management office a knowledge broker in project-based organisations. International Journal of Project Management. 31(1). pp.31-42.

- Ramasesh, R. V. and Browning, T. R., 2014. A conceptual framework for tackling knowable unknown unknowns in project management.Journal of Operations Management. 32(4). pp.190-204.

- Robichaud, L .B. and Anantatmula, V. S., 2010. Greening project management practices for sustainable construction. Journal of Management in Engineering, 27(1), pp.48-57.

- Robichaud, L. B. and Anantatmula, V. S., 2010. Greening project management practices for sustainable construction. Journal of Management in Engineering. 27(1). pp.48-57.

- Ru, X. W. and et. al. ,2013. Municipal Infrastructure Projects Management and Decision-making Support System Based on GIS. In Advanced Materials Research (Vol. 726, pp. 4596-4599). Trans Tech Publications.